Optimization and characterization of LPCVD TiB2 for ULSI applications

Choi,Ruggles,Osburn,Xing

, p. 3053 - 3061 (1991)

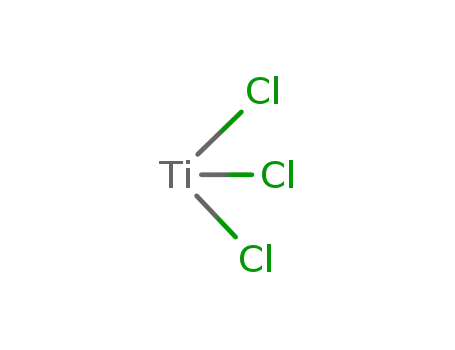

The chemical vapor deposition of TiB2 fr...

Effect of Ni content on the products of Ni-Ti-B system via self-propagating high-temperature synthesis reaction

Huang,Wang,Li,Yin,Jiang

, p. 286 - 291 (2008)

The effect of Ni content on the products...

Chemical and electrochemical behavior of titanium diboride in cryolite-alumina melt and in molten aluminum

Devyatkin,Kaptay

, p. 107 - 109 (2000)

Titanium diboride is the most perspectiv...

High critical current density of MgB2 bulk superconductor doped with Ti and sintered at ambient pressure

Zhao,Feng,Cheng,Zhou,Wu,Machi,Fudamoto,Koshizuka,Murakami

, p. 1154 - 1156 (2001)

Ti-doped MgB2 superconductors with diffe...

Preparation of TiB2 and ZrB2. Influence of a mechano-chemical treatment on the borothermic reduction of titania and zirconia

Millet,Hwang

, p. 351 - 355 (1996)

TiB2 and ZrB2 have been synthesized by a...

Low-temperature densification of TiN-TiB2 composites through reactive hot pressing with excess Ti additions

Rangaraj, Lingappa,Divakar, Canchi,Jayaram, Vikram

, p. 311 - 317 (2009)

Reactive hot pressing of Ti and BN powde...

Processing and properties of TiB2 with MoSi2 sinter-additive: A first report

Murthy,Basu,Balasubramaniam,Suri,Subramanian,Fotedar

, p. 131 - 138 (2006)

The densification of non-oxide ceramics ...

Determination of the thermodynamic stability of TiB2

Jain, Ashish,Pankajavalli,Anthonysamy,Ananthasivan,Babu,Ganesan,Gupta

, p. 747 - 752 (2010)

The standard free energy of formation of...

Effect of KCl, NaCl and CaCl2 mixture on volume combustion synthesis of TiB2 nanoparticles

Nekahi, Atiye,Firoozi, Sadegh

, p. 1377 - 1383 (2011)

Preparation of titanium diboride (TiB2) ...

Mechanochemical synthesis and pressureless sintering of TiB2-AlN composites

Kim, Hyung-Jong,Choi, Heon-Jin,Lee, June-Gunn

, p. 1022 - 1024 (2002)

TiB2-AlN composites have been fabricated...

Compositional and structural changes in TiB2 films induced by bias, in situ and post-deposition annealing, respectively

Pelleg, Joshua,Sade,Sinder,Mogilyanski

, p. 118 - 127 (2006)

Structural changes in TiB2 films were in...

Sn-flux syntheses, characterizations and bonding analyses of OsB and TiB2

Fokwa, Boniface P.T.,Misse, Patrick R.N.,Gille?en, Michael,Dronskowski, Richard

, p. 339 - 342 (2010)

Single-phase crystalline powder of the t...

Ball milling-induced combustion in powder mixtures containing titanium, zirconium, or hafnium

Takacs

, p. 75 - 84 (1996)

Ball milling induces self propagating hi...

A convenient solid-state reaction route to nanocrystalline TiB2

Shi, Liang,Gu, Yunle,Chen, Luyang,Yang, Zeheng,Ma, Jianhua,Qian, Yitai

, p. 192 - 194 (2004)

Nanocrystalline titanium diboride (TiB2)...

Influence of stearic acid on mechanochemical reaction between Ti and BN powders

Byun, Jung-Soo,Shim, Jae-Hyeok,Cho, Young Whan

, p. 149 - 156 (2004)

The influence of stearic acid as a proce...

Effects of TiC doping on the upper critical field of MgB2 superconductors

Yan,Zhou,Yan,Lu

, p. 1032 - 1035 (2008)

TiC doped MgB2 bulks were fabricated by ...

Mechanism of the cathode process in the electrochemical synthesis of TiB2 in molten salts. I. The synthesis in an all-fluoride electrolyte

Makyta,Matiasovsky,Taranenko

, p. 861 - 866 (1989)

The mechanism of the cathode process in ...

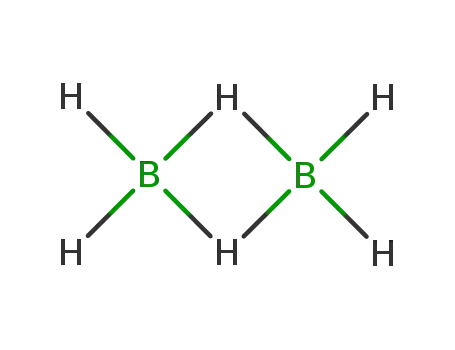

Growth inhibition to enhance conformal coverage in thin film chemical vapor deposition

Kumar, Navneet,Yanguas-Gil, Angel,Abelson, John R.,Daly, Scott R.,Girolami, Gregory S.

, p. 17660 - 17661 (2008)

-

Properties of titanium and zirconium diborides obtained by self-propagated high-temperature synthesis

Radev,Marinov

, p. 48 - 51 (1996)

Self-propagated high-temperature synthes...

In situ synthesis of ceramic composite materials in the Ti-B-C-N system by a mechanically induced self-sustaining reaction

Aviles, Miguel A.,Chicardi, Ernesto,Cordoba, Jose M.,Sayagues, Maria J.,Gotor, Francisco J.

, p. 2133 - 2139 (2012)

The synthesis of multicomponent ceramic ...

Properties of TiB2 powders obtained in a mechanochemical way

Radev,Klisurski

, p. 39 - 41 (1994)

Mechanochemical synthesis of TiB2 powder...

The effect of surface oxides during hot pressing of TiB2

Jensen, Morten Sundheim,Einarsrud, Mari-Ann,Grande, Tor

, p. 623 - 630 (2009)

Hot pressing of TiB2 has been investigat...

Simultaneous spark plasma synthesis and densification of TiC-TiB 2 composites

Locci, Antonio M.,Orru, Roberto,Cao, Giacomo,Munir, Zuhair A.

, p. 848 - 855 (2006)

The simultaneous synthesis and densifica...

A reduction-boronation route to nanocrystalline titanium diboride

Chen, Luyang,Gu, Yunle,Shi, Liang,Yang, Zeheng,Ma, Jianhua,Qian, Yitai

, p. 231 - 233 (2004)

Nanocrystalline titanium diboride (TiB2)...

In situ synthesis and properties of Ti3AlC2/TiB 2 composites

Li, Chao,Li, Meishuan,Zhou, Yanchun,Zhang, Jie,He, Lingfeng

, p. 3615 - 3620 (2007)

In order to improve the mechanical prope...

Effect of Cu content on the reaction behaviors of self-propagating high-temperature synthesis in Cu-Ti-B4C system

Liang,Wang,Yang,Zhao,Jiang

, p. 113 - 118 (2008)

The SHS reaction behaviors of the Cu-Ti-...

Morphology and deposition rates of TiB2 prepared by chemical vapour deposition of TiCl4 + B2H6 system

Mukaida,Goto,Hirai

, p. 1069 - 1075 (1990)

Titanium diboride (TiB2) is a promising ...

A facile one-step route to nanocrystalline TiB2 powders

Chen, Luyang,Gu, Yunle,Qian, Yitai,Shi, Liang,Yang, Zeheng,Ma, Jianhua

, p. 609 - 613 (2004)

Nanocrystalline titanium diboride (TiB2)...

PLASMA ENHANCED CHEMICAL VAPOR DEPOSITION OF TITANIUM DIBORIDE FILMS.

Williams

, p. 43 - 45 (1985)

Thin films of titanium borides were depo...

Structure of TiB2 produced by dynamic ion mixing

Riviere,Guesdon,Delafond,Denanot

, p. 477 - 486 (1988)

The technique of dynamic ion mixing is b...

Synthesis of nano-sized titanium diboride in a melt of anhydrous sodium tetraborate

Volkova,Shulga,Shilkin

, p. 819 - 821 (2012)

X-ray powder diffraction, scanning elect...

Electrochemical deposition of TiB2 in high temperature molten salts

Fastner,Steck,Pascual,Fafilek,Nauer

, p. 32 - 35 (2008)

The electrochemical deposition of TiB2 o...

Effect of titanium carbide addition on the thermoelectric properties of B4C ceramics

Cai,Nan,Paderno,McLachlan

, p. 523 - 526 (2000)

TiB2/B4C composite ceramics are prepared...

Preparation of titanium diboride nanopowder

Kravchenko,Torbov,Shilkin

, p. 614 - 616 (2010)

We have studied the reaction between NaB...

Reactive hot pressing of titanium nitride-titanium diboride composites at moderate pressures and temperatures

Rangaraj, Lingappa,Divakar, Canchi,Jayaram, Vikram

, p. 1872 - 1878 (2004)

Dense composites in the Ti-B-N system ha...

Preparation of TiB2 sintered compacts by hot pressing

Itoh, Hideaki,Naka, Shigeharu,Matsudaira, Tsuneaki,Hamamoto, Hiroshi

, (1990)

A sintered compact of titanium diboride ...

Electrochemical synthesis of TIB2 layers out of FLiNaK electrolyte in the presence of TaCl5 additive

Rybakova,Babushkina,Artner,Nauer

, p. D593-D599 (2010)

TiB2 coatings on Mo substrates were elec...

Low temperature electrical resistivity studies and search for superconductivity in Ti-B system

Kutty,Pillai,Karunakaran,Vaidya

, p. 1123 - 1126 (1989)

Resistivity of TiBx alloy has been measu...

Effect of HCl concentration on TiB2 separation from a self-propagating high-temperature synthesis (SHS) product

Demircan, Umut,Derin, Bora,Yücel, Onuralp

, p. 312 - 318 (2007)

This paper presents a synthesis of TiB2 ...

Formation of titanium nitride by mechanical milling and isothermal annealing of titanium and boron nitride

Ding,Yao,Qiu,Bai,Guo,Xue,Wang,Zhou,Su

, p. 77 - 81 (2005)

The formation of titanium nitride with r...

Acid leaching of SHS produced magnesium Oxide/titanium diboride

Lok, Jonathan Y.,Logan, Kathryn V.,Payyapilly, Jairaj J.

, p. 26 - 31 (2009)

The stoichiometric self-propagating high...

Consolidation of combustion-synthesized titanium diboride-based materials

Hoke,Meyers

, p. 275 - 284 (1995)

The quasi-static consolidation in uniaxi...

Synthesis of ultrafine titanium diboride particles by rapid carbothermal reduction in a particulate transport reactor

Saito, Takeyasu,Fukuda, Tomoyuki,Maeda, Hideaki,Kusakabe, Katsuki,Morooka, Shigeharu

, p. 3933 - 3938 (1997)

Ultrafine TiB2 powders were synthesized ...

Synthesis of TiB2 by electric discharge assisted mechanical milling

Calka,Oleszak

, p. 346 - 348 (2007)

In this study, synthesis of titanium dib...

Reaction control of TiB2 formation from titanium metal and amorphous boron

Itoh,Matsudaira,Naka,Hamamoto

, p. 420 - 424 (1989)

TiB2 powder was synthesized by a control...

A mild solvothermal route to nanocrystalline titanium diboride

Gu, Yunle,Qian, Yitai,Chen, Luyang,Zhou, Fu

, p. 325 - 327 (2003)

Titanium diboride (TiB2) has been synthe...

Homogeneous TiB2 ceramics achieved by electric current-assisted self-propagating reaction sintering

Salamon, David,Eriksson, Mirva,Nygren, Mats,Shen, Zhijian

, p. 3303 - 3306 (2007)

Using spark plasma sintering techniques,...

New criteria for the applicability of combustion synthesis: The investigation of thermodynamic and kinetic processes for binary Chemical Reactions

Tan, Xiaoming,Su, Xianli,Yan, Yonggao,Uher, Ctirad,Zhang, Qingjie,Tang, Xinfeng

supporting information, (2021/01/07)

Combustion synthesis is a novel techniqu...

Novel sustainable silicothermic synthesis of phase-pure TiB2 fine powder

Ke, Changming,Ni, Yue'e,Qin, Zhi,Wang, Jingran,Zhang, Jinhua

, (2020/04/28)

Phase pure TiB2 powder of 100–400 nm was...

Sequence of phase evolution during mechanically induced self-propagating reaction synthesis of TiB and TiB2via magnetically controlled ball milling of titanium and boron powders

Oghenevweta,Wexler,Calka

, p. 380 - 391 (2017/02/05)

Mechanically induced self-propagating re...

Influence of friction stir processing on microstructure and properties of AA7075/TiB2 in situ composite

Rajan, H.B. Michael,Dinaharan,Ramabalan,Akinlabi

, p. 250 - 260 (2015/11/09)

Friction stir processing (FSP) is a nove...